Archives: Product

Coming soon

Mambaroll Conveyor Rollers

FLENDER Gear Units for Rotary Kilns

The rotary kiln is the core of lime and cement clinker production. In the slightly inclined cylindrical tube, which rotates around its longitudinal axis during the firing process, the lime powder is heated up to 1450 °C and burned into cement clinker. The rotation has both a transport and an air injection effect.

The length of such a kiln can be well over 100 meters. In this type of kiln, the limestone is added at the slightly higher end and slowly passes through the kiln due to the rotation. All drive elements must also be inclined accordingly. FLENDER offers the latest drive systems for rotary kilns.

FLENDER Gear Units for Trolley Traveling and Traveling Gears

High operational reliability for trolley travelling-gear and travelling-gear drives

Whether it is trolley travelling-gear, or rail-borne or tyre-borne travelling-gear, every application makes quite specific demands of gear-unit design that have to be taken into consideration. The FLENDER gear-unit series optimised for these areas of application stands out for highest possible reliability, highest possible quality and long service life, whatever the loads placed on the gear units, for example, on container cranes. Output torques from 10,000 up to 75,000 Nm can be realised.

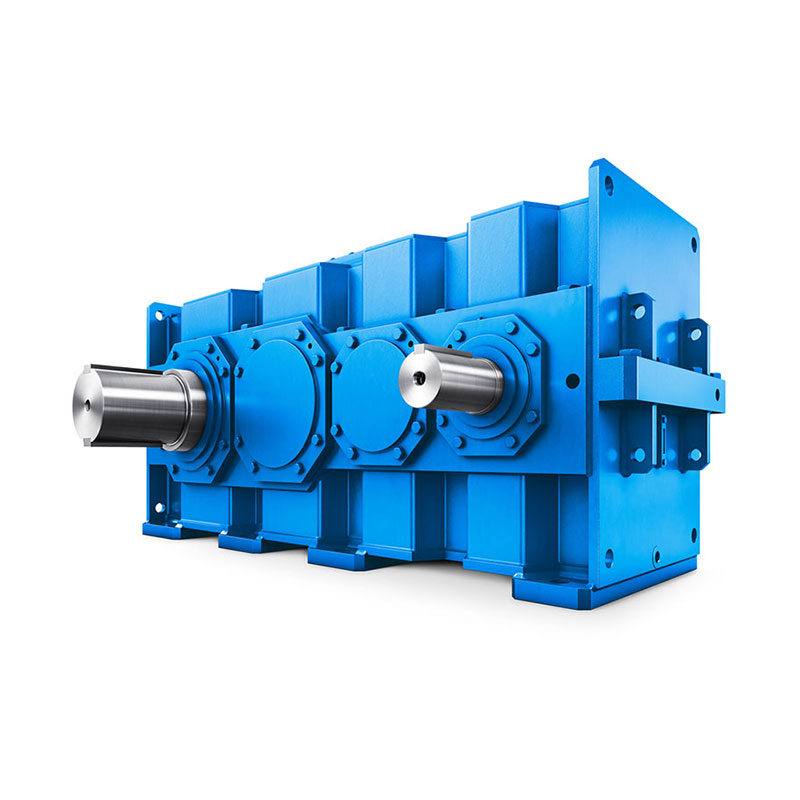

FLENDER Gear Units for Hoisting and Luffing Gears

Precision and reliability for high performance

FLENDER gear units for lifting and luffing gears are economical and efficient. Alongside the extensive range of extremely compact standard gear units FLENDER offers application-specific gear units with a large overall center distance that enable parallel fitting of motor and winding drum, even with large drum and motor diameters. The gear-unit series is ideally suited for operation on container cranes and bridge cranes, that is, where a parallel motor-and-winding-drum arrangement is called for. FLENDER industrial gear units for lifting and luffing gears are available in a broad transmission range for torques ranging from 10,000 up to 1,400,000 Nm.

FLENDER CHG – robust special solutions for lifting and luffing gears

The new FLENDER CHG gear unit offers operational reliability and optimum efficiency. The new gear-unit series has been developed in close collaboration with our customers on the basis of many decades of experience in the engineering of drives for cranes.

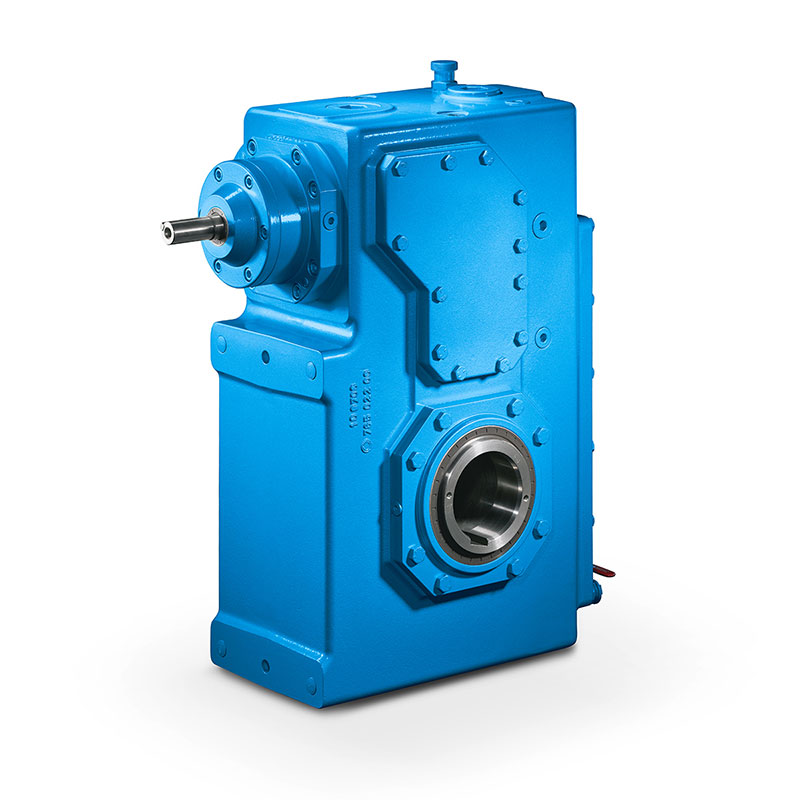

FLENDER KMP

The proven all rounder

The KMP series offers high flexibility with constant product quality for every kind of coal mill. 18 sizes in a torque range of up to 700,000 Nm leave nothing to be desired.

KMP gear units are very reliable components due to the special tooth geometry, bearing selection and rigid housings.

Customers profit from short delivery and an attractive price-performance-ratio.

FLENDER FLUDEX Fluid Coupling

- Hydrodynamic fluid coupling

- Nominal output from 1.2 kW up to 2,500 kW with 15 sizes

- Temperature range: from –40 °C to +50 °C

Soft and safe: Especially within tough applications, drive components and processing machines are subject to extreme loads.

FLUDEX® couplings limit start and maximum torque within the drive train and serve as starting aids for the motor and as overload protection in the case of an incident.

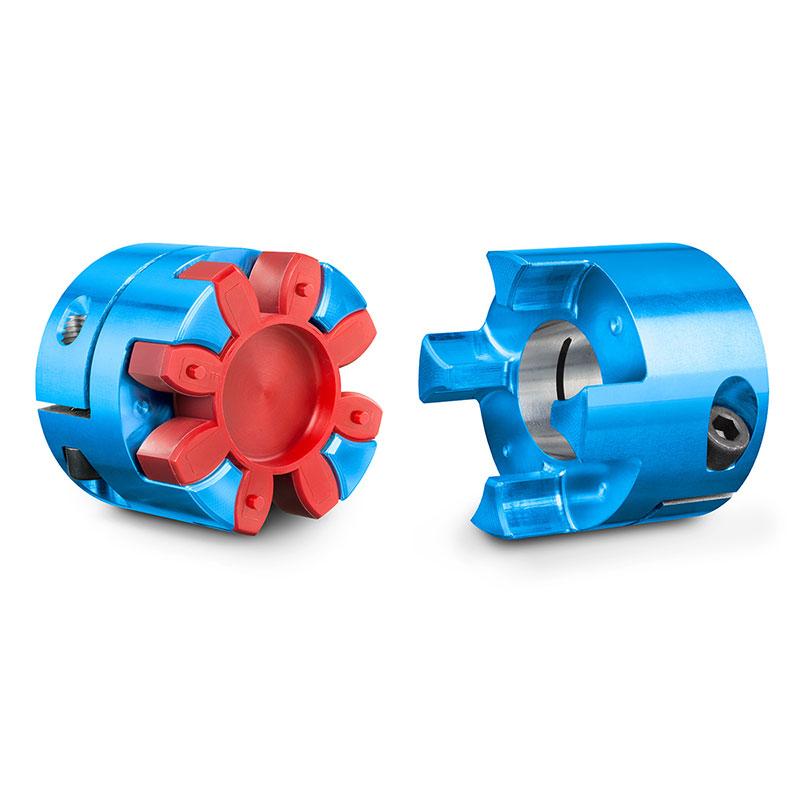

FLENDER BIPEX-S Claw Coupling

- Vibration-damping and electrically insulating claw coupling

- Nominal torque range from TKN = 0.5 Nm to 655 Nm with ten sizes

- Temperature range: from –50 °C to +120 °C

Backlash-free applications – easy solutions: In the area of backlash-free couplings we offer you a large range of types and sizes in the two model ranges BIPEX-S® und SIPEX® for problem-free installation.

The vibration-damping and electrically insulating plug-in BIPEX-S elastomer coupling is almost completely maintenance- and wear-free and has an exceedingly low moment of inertia.

FLENDER ELPEX-B Rubber Tyre Coupling

- Highly flexible, backlash-free tire coupling

- Nominal torque range from TKN = 24 Nm up to 14,500 Nm with 15 sizes

- Temperature range: from –50 °C to +50 °C for natural rubber materials, from –15 °C to +70 °C for chloroprene rubber

Flexible and adaptable: Highly flexible ELPEX-B® couplings transmit torques without circumferential backlash in machines with non-uniform torque characteristics. They are resistant to wear and maintenance-free. The hubs of the ELPEX-B couplings are made of high-quality cast iron or steel. The torque is transmitted by a flexible tire reinforced with a cord ply.