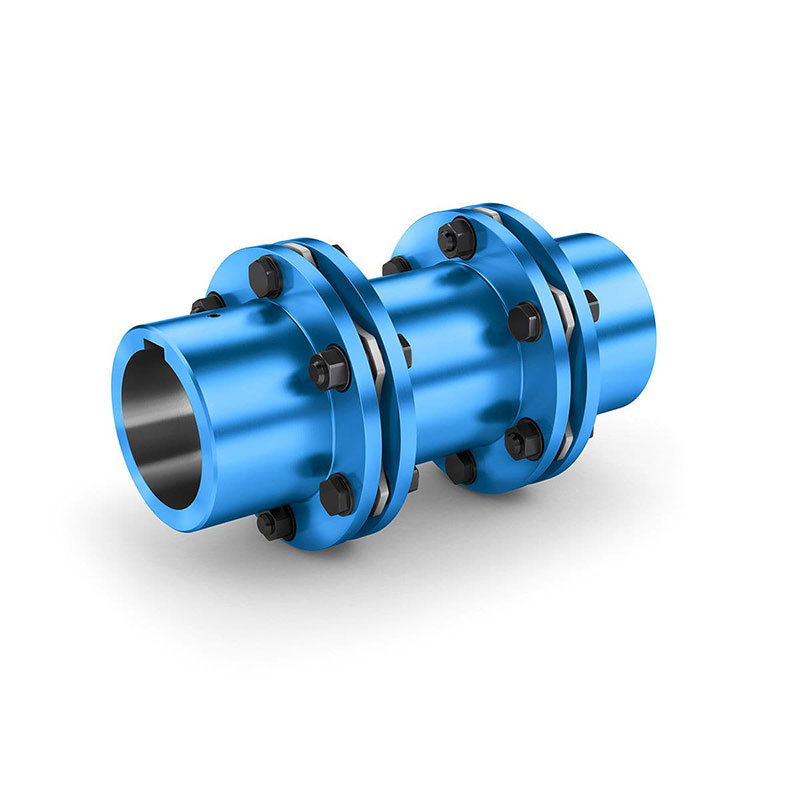

FLENDER N-ARPEX All-steel Coupling

- Backlash-free, torsionally rigid all-steel multi-disk coupling

- Nominal torque range from TKN = 350 Nm to 28,000 Nm

- Temperature range: from –50 °C to +280 °C

The best-performing coupling on the market

Investment costs, lifecycle costs, power-to-weight ratio, fitness for use and the cost of purchasing couplings are key considerations for equipment manufacturers.

With the introduction of the new N-ARPEX® all-steel multi-disk coupling Flender is continuing the success story of the proven ARPEX® series of couplings.

The N-ARPEX is the consistent further development of the ARPEX into what is at present the best-performing coupling on the market – a leap in performance that in this size could only be achieved by means of various design features.

With our all-steel couplings, the reliable transmission of torque between the shafts to be connected is backlash-free, torsionally rigid and flexurally elastic.

This enables them to compensate for axial, angular and radial misalignment. Our multi-disk couplings are not prone to wear and are maintenance-free.

The couplings have been designed for use in potentially explosive environments as defined in Directive 2014/34/EU (ATEX) and comply with the requirements in standards API 610 and API 671.

Your benefits at a glance

- Lower costs through higher performance

An optimized diskpack and a revised component design enable transmission of very high torques and speeds. - Low bearing loads through low weight

A marked increase in bore capacities with standard hubs increases performance capability and lowers the N-ARPEX’s weight. - Versatility for maximum fitness for use

Its suitability for use at low temperatures between –50 °C and +280 °C and its high misalignment capacities of up to 1° enable the N-ARPEX to be used for many different purposes in special conditions. - Easy selection and reduction in storage costs

The bundling of the ARPEX ARS®, ARC® and ARP® series together to make a single series results in a reduction in complexity from 42 to 14 couplings. Thus, storage costs are reduced. Choosing the desired coupling is much easier.

Made in Germany, in use worldwide

- Mining and Cement: conveyor belts, apron conveyors, bucket elevators, tube mills, bucket excavators, crushers, roller presses, separators, heating technology, slurry pumps

- Steel Production: shears, reversing rolling mills, pilger rolling mills

- Cranes: hoisting and luffing gear systems, slewing gear systems, trolley and travel gear systems

- Marine and Shipbuilding: single-engine ships, multi-engine ships, dredgers, generator gearboxes, installation vessels

- Oil and Gas: installation vessels, pumps, fans, compressors, air condensers, jack-up rigs

- Power Generation: air condensers, generators, gas turbines, cooling towers, water turbines, boiler feed pumps

- Chemicals and Pharmaceuticals: driers, pumps and compressors, mixers, cooling towers, agitators, reactors

- Plastics and Rubber: single- and double-screw extruders

- Pulp and Paper: waste paper, wet section, dry section, smoothers and cylinders, reel winders, coating machines, calenders, wastewater purification plants

- Water and Wastewater: aerators, water screw pumps

- Food and Beverage: lauter tuns, reactors, agitators, mixers, filling systems

- Sugar: generators, steam turbines, sugar cane mills

- Passenger Transport: cable cars

- Other fields of application: test benches, wood milling, packaging machines