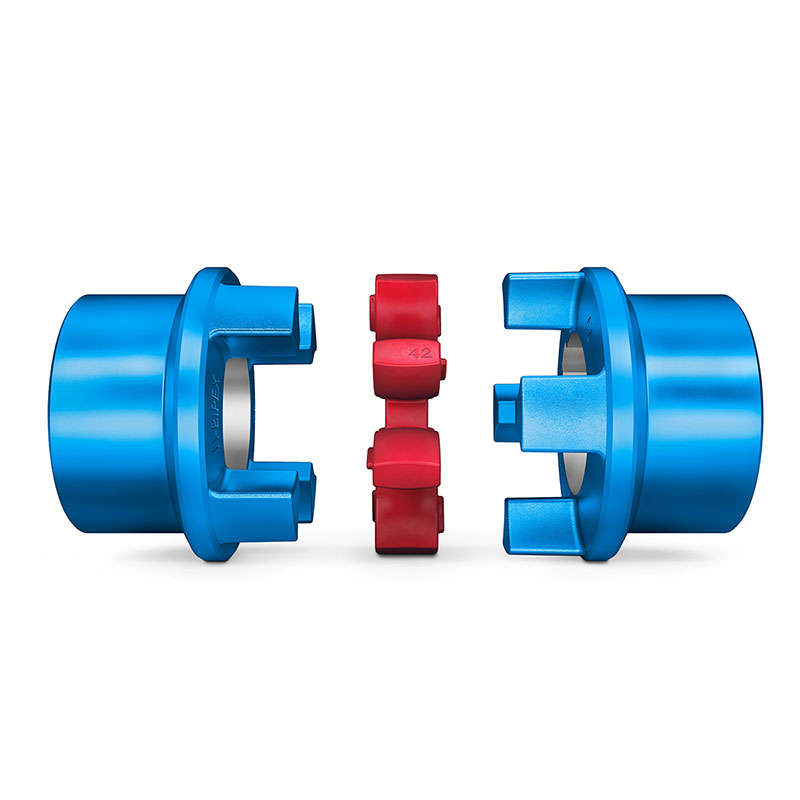

FLENDER N-BIPEX Claw Coupling

- Damping shaft coupling that can be used universally to compensate for shaft misalignments

- Nominal torque range from TKN = 12 Nm up to 4,650 Nm with 10 sizes

- Temperature range: from – 50 °C to +100 °C

The coupling portfolios normally found on the market consist of comparable couplings with a maximum permissible torque corresponding to twice the coupling’s nominal torque. To be on the safe side – for example during the run-up phase of an asynchronous motor with typical starting torques and tilting moments – it is often necessary to fall back on the next-largest coupling size. If high rotational speeds or relatively large bores need to be taken into account, the market often offers costly steel solutions.

Your benefits at a glance

- High torque reserves (maximum torque = 3 × nominal torque) to effortlessly absorb torque peaks

- Reduced complexity and lower storage costs due to the use of a single hub to meet all requirements

- High-quality elastomers that ensure uniform load distribution and thus an optimal service life under all conditions

- Suitable for use in potentially explosive environments; certified according to 2014/34/EU (ATEX)

- Available with taper clamping bush

Made in Germany, in use worldwide

- Mining and Cement: separators, heating technology

- Steel Production: shears, straightening machines

- Oil and gas: pumps, fans, compressors, air condensers

- Power Generation: pumps, fans, compressors, air condensers, water turbines

- Chemicals and Pharmaceuticals: driers, lauter tuns, pumps, fans, compressors, mixers, agitators, reactors

- Pulp and Paper: wastewater purification plants

- Water and Wastewater: aerators, water screw pumps

- Food and Beverage: lauter tuns, reactors, agitators, mixers

- Railway Vehicles: railway couplings