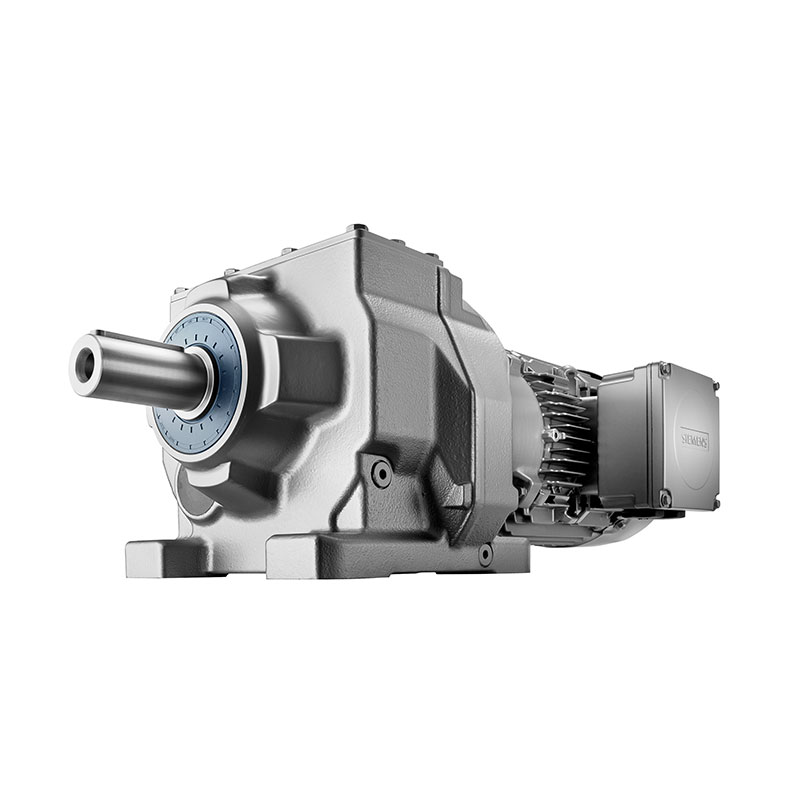

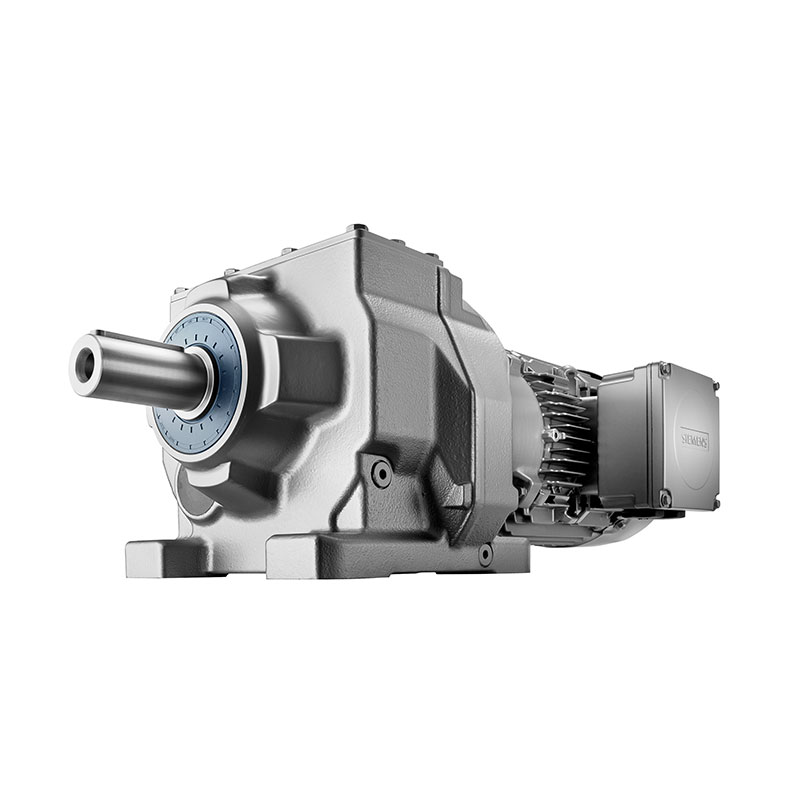

SIMOGEAR makes the change easy

Having market conform connecting dimensions, the latest SIMOGEAR geared motor are 1:1 compatible to the current standard. SIMOGEAR is an economic alternative easy for replacements in already existing installations or to implement in new designs. Surely, the new series fits the Siemens DriveTrain in an optimal way.

- High gear ratios (shank pinion)

- High Torque

- Best IEC Adaptor in the market

- Very energy efficient (efficiencies of 98% per stage)

- High power range

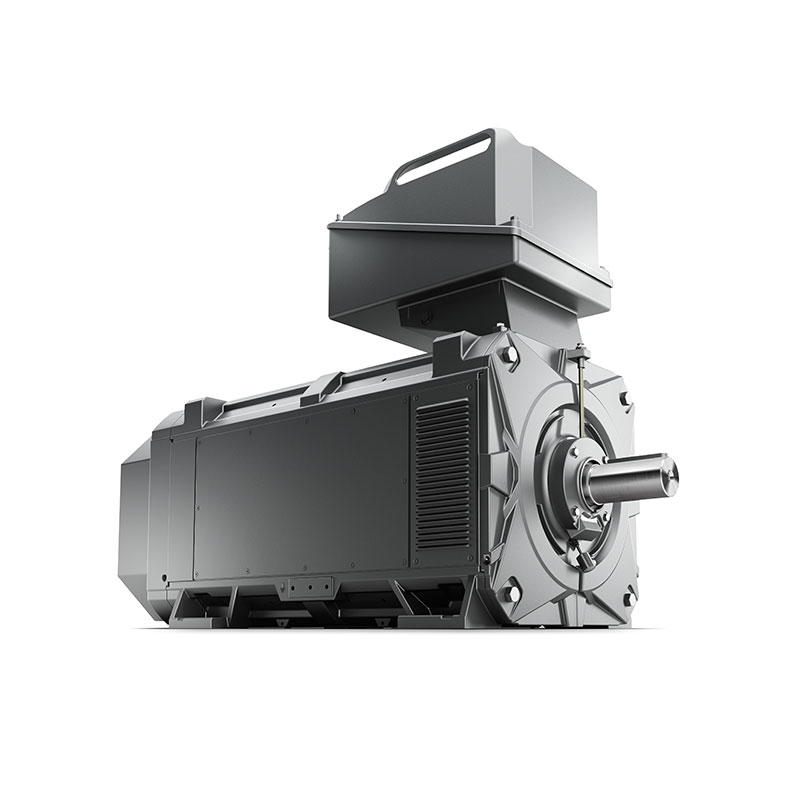

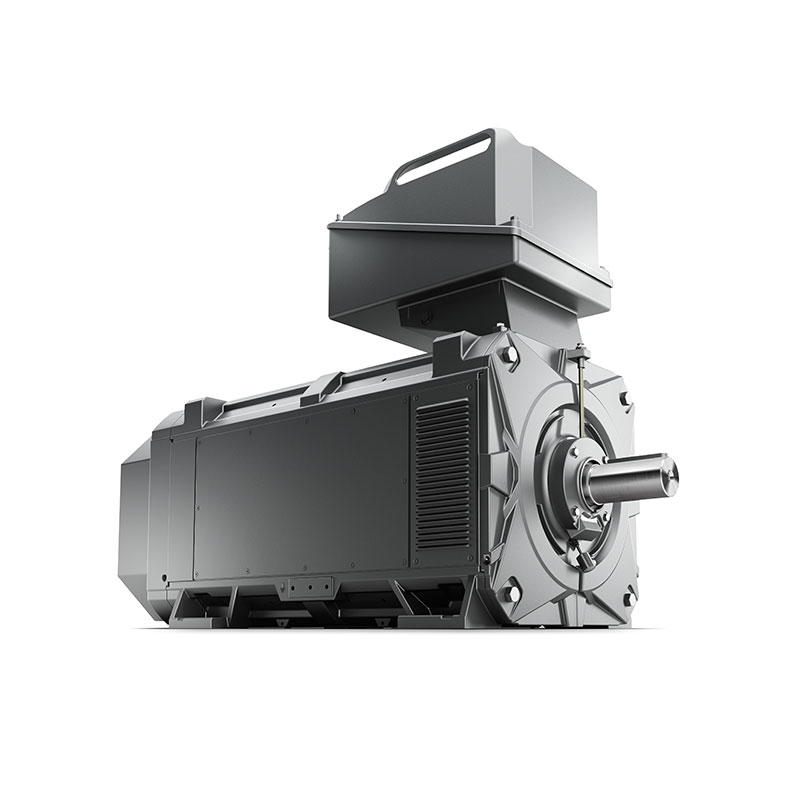

In the power range from 200 kW upwards SIMOTICS FD is the basis for a complete, cost-effective system comprised of a motor and drive with a high power density. Using a wide range of versions, the motors can be flexibly and efficiently used in the widest range of applications and sectors.

The motors are rugged and durable as a result of their cast iron frame. The water-cooled motors allow an extensive range of other applications to be addressed.

The Severe Duty motors with gray cast iron frames are especially rugged. This makes them the first choice for applications in the toughest of environmental conditions. They have outstanding performance both in dust loading and in vibration as well as in the aggressive atmospheres that prevail in the petrochemical and process industries.

Their design supports optimized heat dissipation and offers the same handling as the general purpose variants.

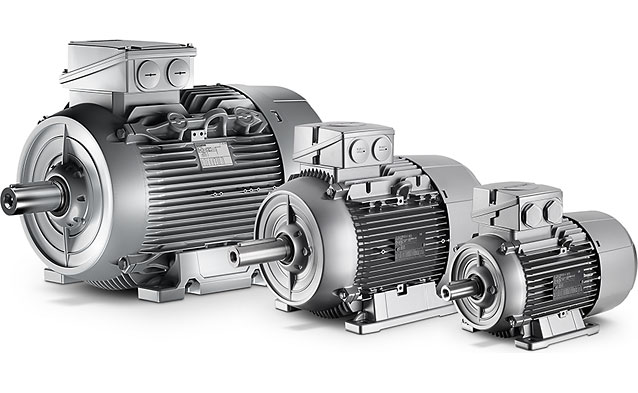

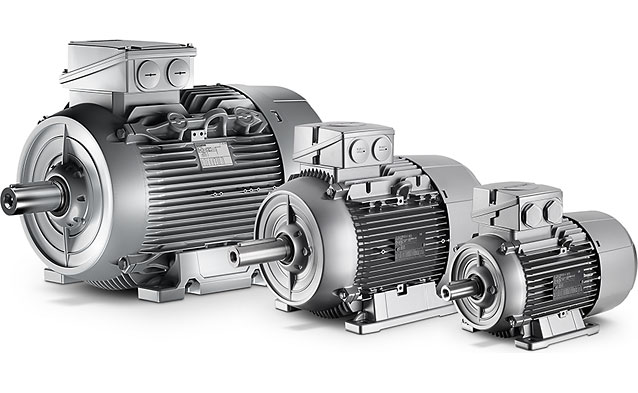

General Purpose motors with aluminum frame are suitable for a wide range of standard drive tasks in the industrial environment. As a result of their especially low weight, they are predestined for pump, fan and compressor applications. However, they are also admirably suited for conveyor technology and lifting equipment.

The proven, for line operation optimized 1LE1 motors are available in the efficiency classes IE1 to IE4. All motors have the same power rating-shaft height-assignment. This means that there are no shaft height jumps – neither for service nor retrofit cases. 1LE1 motors offer a future-proof platform.

Stays cool in hot Conditions

With the E-belt drive series, FLENDER offers a gear-unit range that is at home in extreme ambient conditions. To guarantee a stable operating temperature, highly efficient fans are used.

Specially designed air-guide hoods ensure that the air flows evenly over the entire housing. In combination with the optimised surface the best qualifications for outstanding heat regulation.

Cooling systems represent additional risk potential for many mine operators, as frequently there is no water supply available.

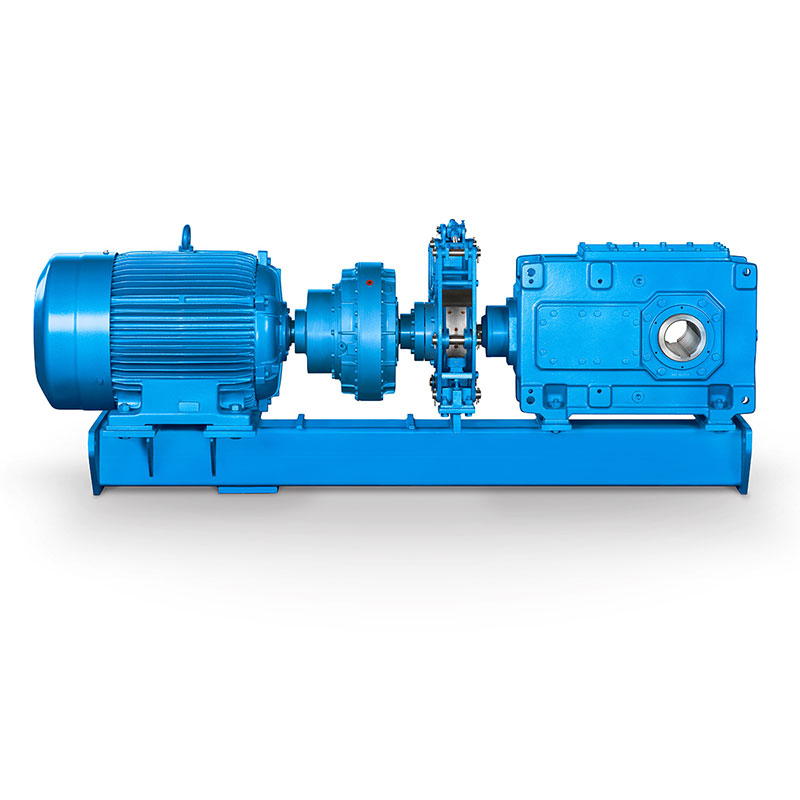

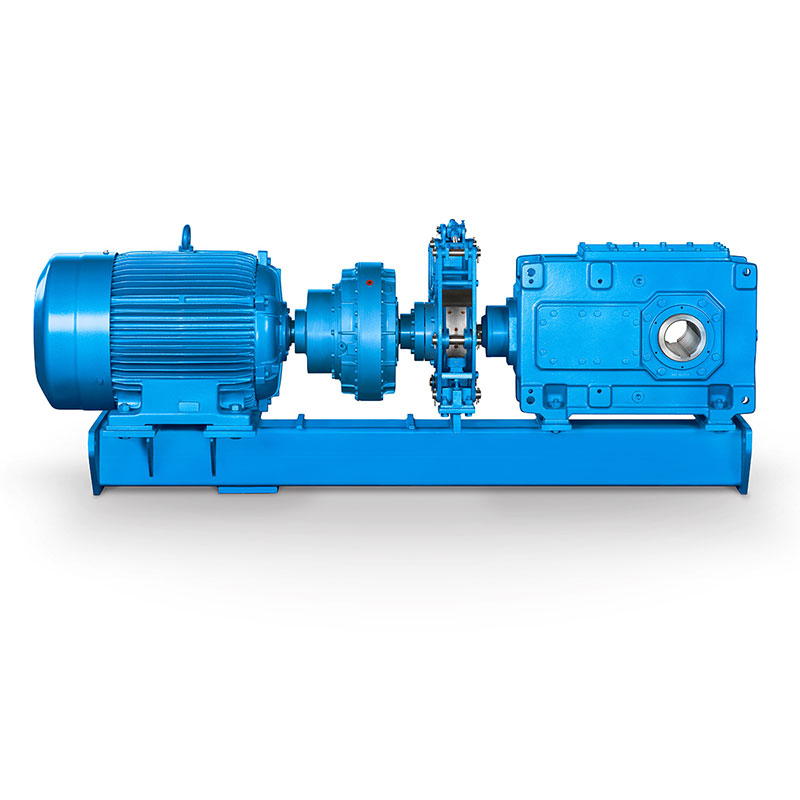

A FLENDER Conveyor Drive System for all Applications

Our extensive module system offers drive solutions from standardized components for every conveyor belt. Due to the use of established standard components customers profit from short delivery times and an excellent price-performance ratio.

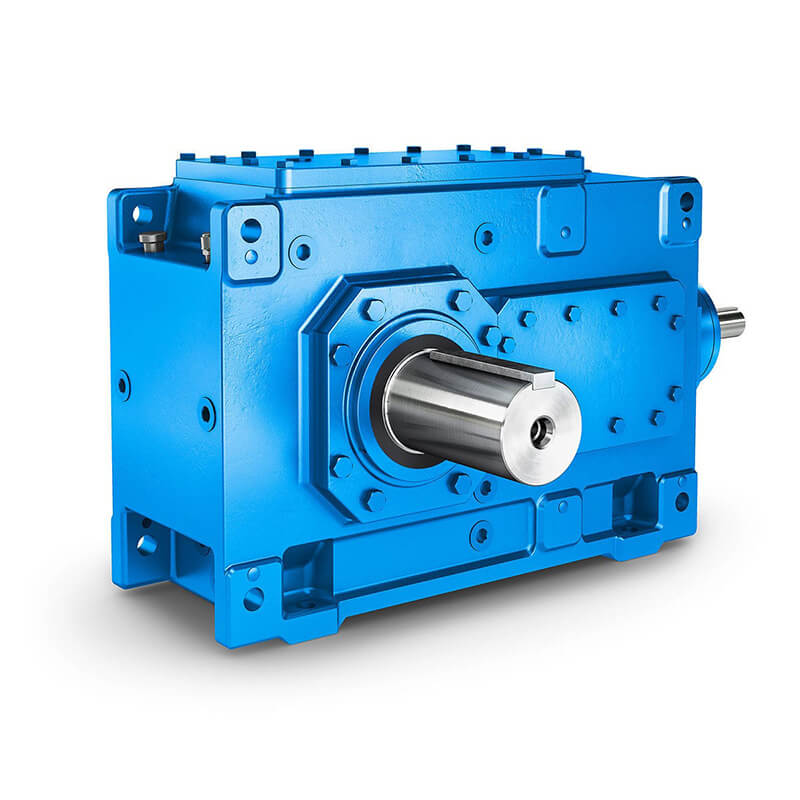

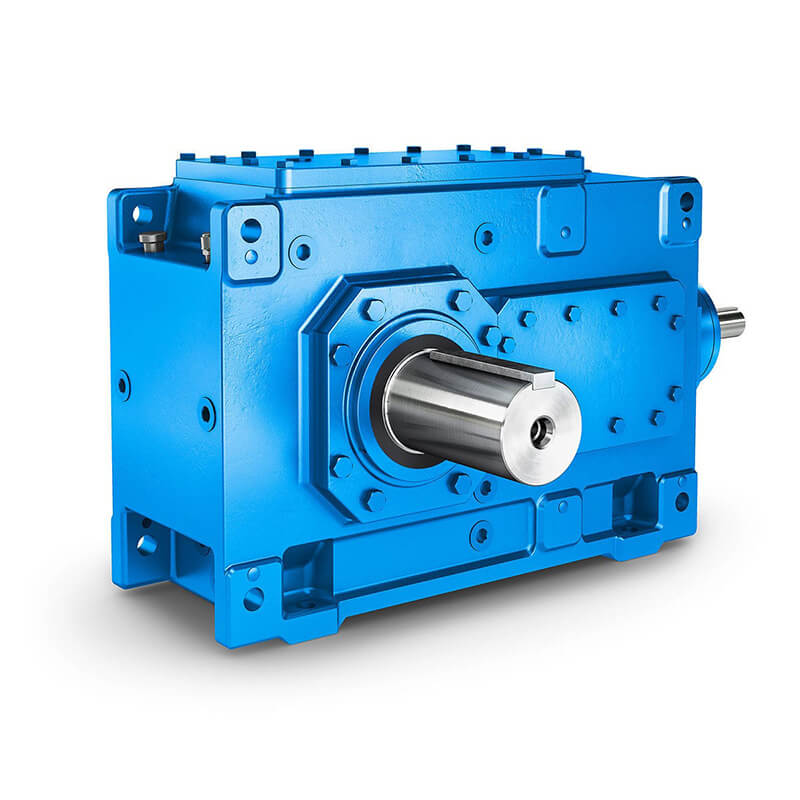

In case the environmental conditions allow it, it is reasonable to arrange cost-effectively a Drive from the highly-developed standard porftolio. This is due to the fact that the modular system with its wide range of gear-units, motors, bell-housings, swing bases and add-on parts does not leave any wishes unfulfilled. The H-conveyor gear units are compact, have a high power density and are available in 25 construction sizes. They are well suited for multiple drives to meet very high power requirements. These belt drives have proved themselves in thousands of applications worldwide.

Bucket elevators serve to vertically transport large masses of bulk material to different heights without creating dust, then dump it. The height to be overcome is frequently more than 200 meters. The weights to be moved are enormous.

The carrying elements in bucket elevators are central or double chain strands, link chains, or belts to which the buckets are attached. The drive is located at the upper station. The features specified for the drives destined for these applications are similar to those for steeply ascending belt conveyors. Bucket elevators require a comparatively high input power.

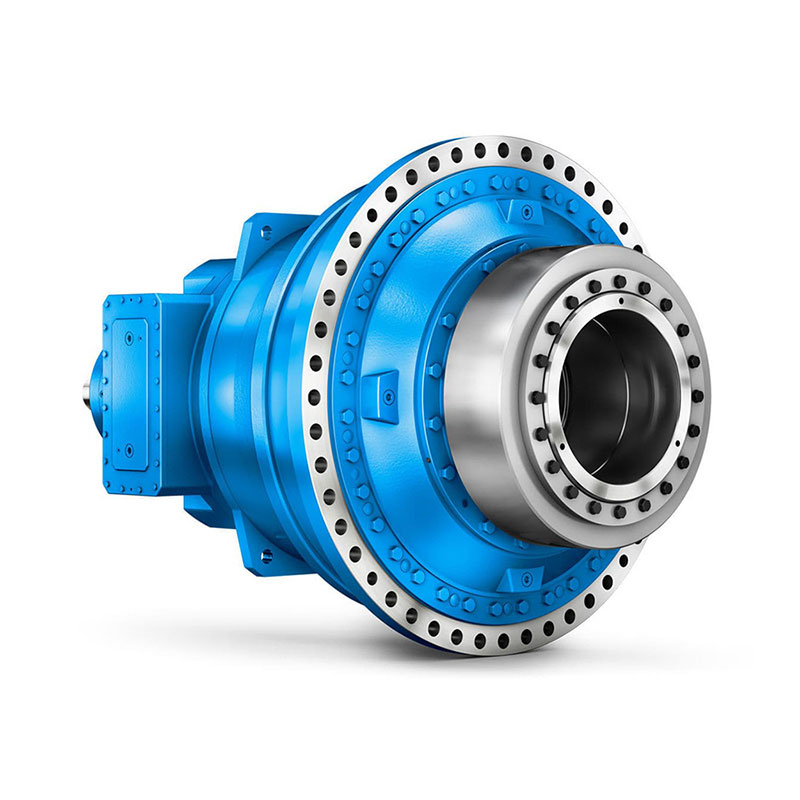

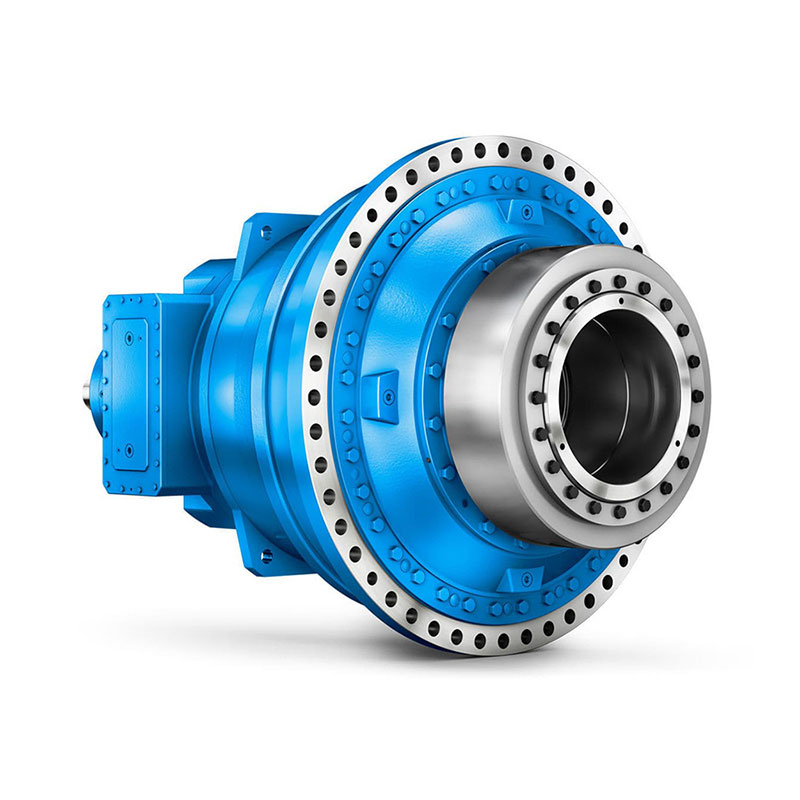

- Planetary gear unit which can be installed horizontally

- Nominal torque range from TKN = 1,700,000 Nm to 5,450,000 Nm with 10 sizes

- Nominal transition range from i = 26 to 112

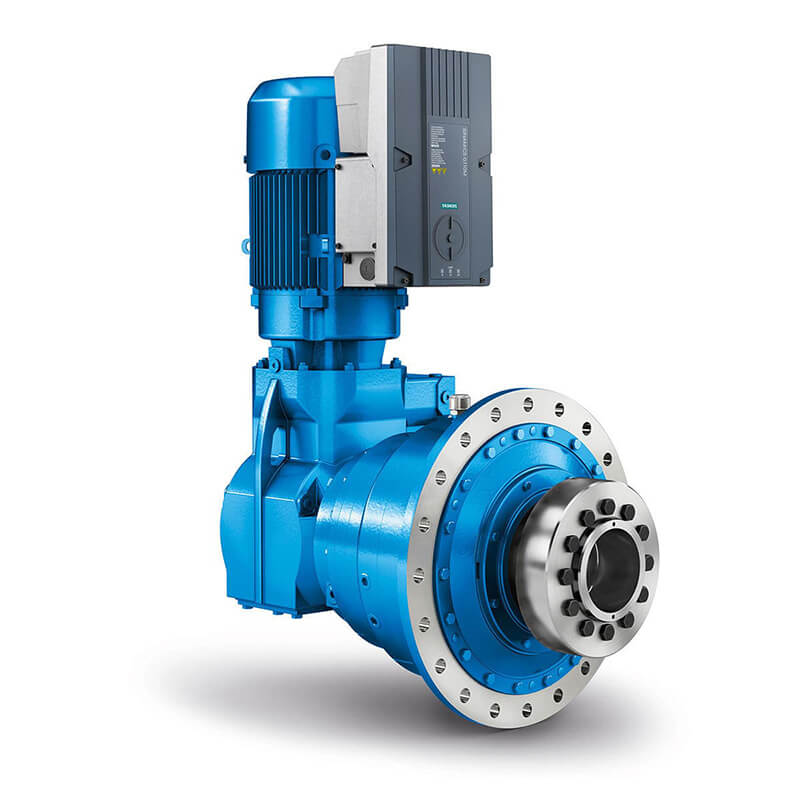

In the world of drive systems the word “premium” has many facets. These result from your expectations on the product and how they are met. With our PLANUREX® 3 series, we have redefined these expectations. PLANUREX 3 represents a new generation of premium planetary gear units that have extremely high power capacity, can be used in a wide range of applications and are setting new benchmarks in terms of quality, flexibility and ease of use.

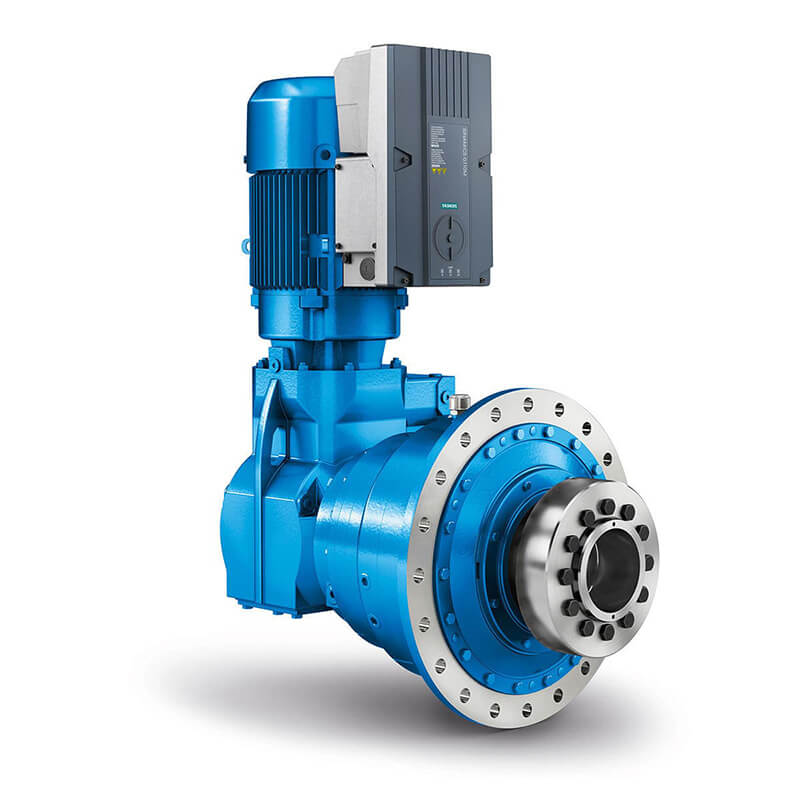

With FLENDER SIP® planetary gear units, we offer you a spectrum of fatigue-resistant, reliable and finely spaced gear unit solutions from 10,000 to 80,000 Nm. The series includes not only the highly integrated planetary gear motor but also maximum conformity with all international motor standards and ensures that quality and performance bear a sensible relationship to life cycle costs and price.

The FLENDER® helical and bevel-helical gear unit portfolio is by far the most comprehensive range of industrial gear units in the world.

It includes a multifaceted range of universal gear units, application-specific gear units and customer-specific solutions.