- Damping shaft coupling that can be used universally to compensate for shaft misalignments

- Nominal torque range from TKN = 12 Nm up to 4,650 Nm with 10 sizes

- Temperature range: from – 50 °C to +100 °C

The coupling portfolios normally found on the market consist of comparable couplings with a maximum permissible torque corresponding to twice the coupling’s nominal torque. To be on the safe side – for example during the run-up phase of an asynchronous motor with typical starting torques and tilting moments – it is often necessary to fall back on the next-largest coupling size. If high rotational speeds or relatively large bores need to be taken into account, the market often offers costly steel solutions.

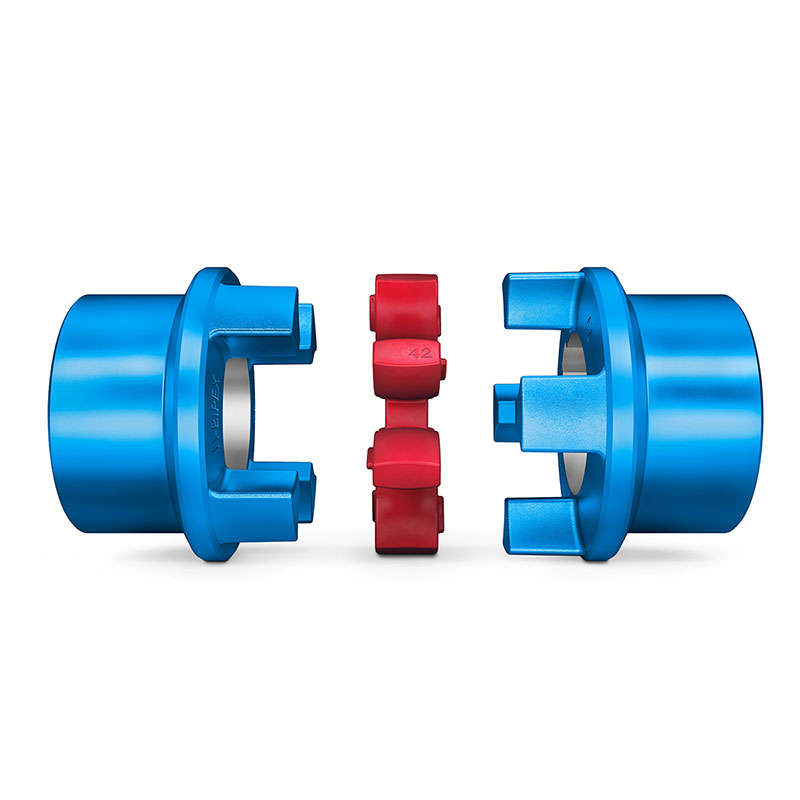

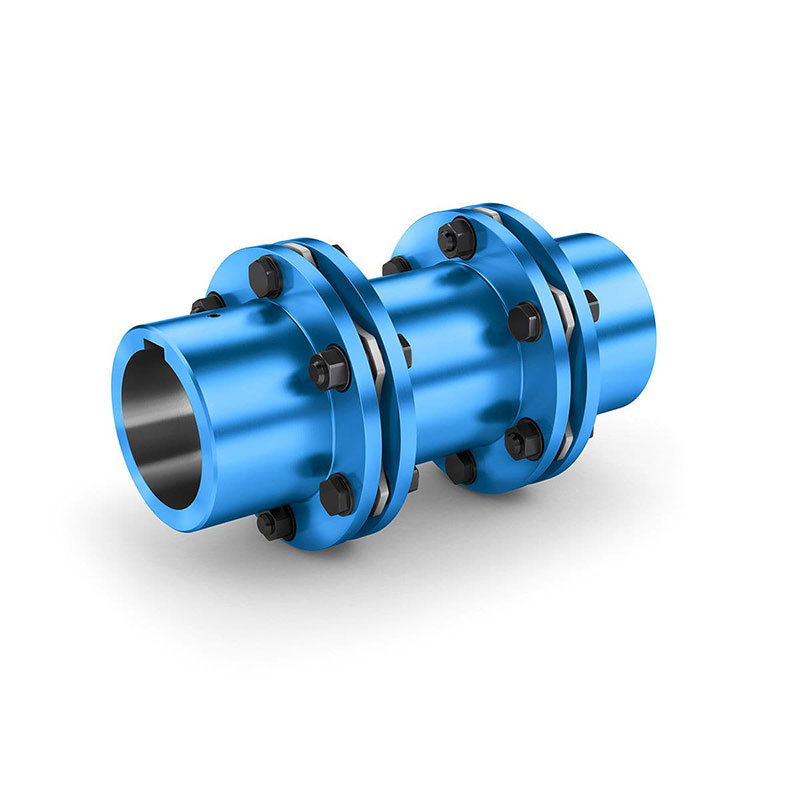

- Damping, fail-safe pin and bush coupling for medium and higher torques

- Nominal torque range from TKN = 200 Nm up to 1,300,000 Nm with 26 sizes

- Temperature range: from –50 °C to +100 °C

RUPEX couplings are used as flexible compensating couplings in all applications requiring a reliable transmission of torque under harsh operating conditions. The conical seats of the buffer pins facilitate mounting and guarantee maintenance-free operation. The optimized shape of the barrelled buffers allows simple plug-in assembly and low circumferential backlash. Many type variants are offered, e. g. with brake disk, axial play limiting device, or brake motor couplings.

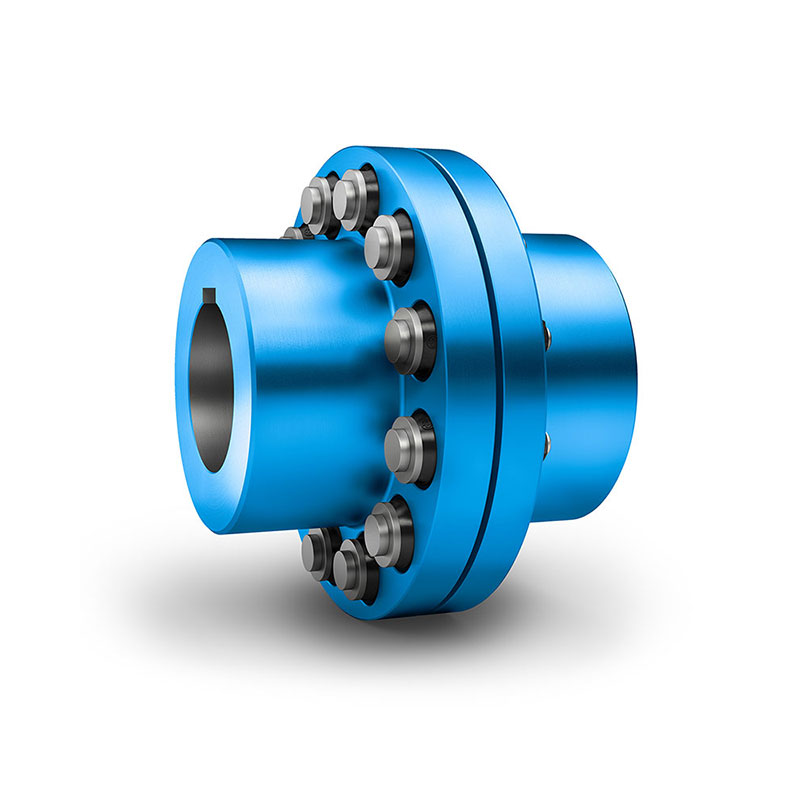

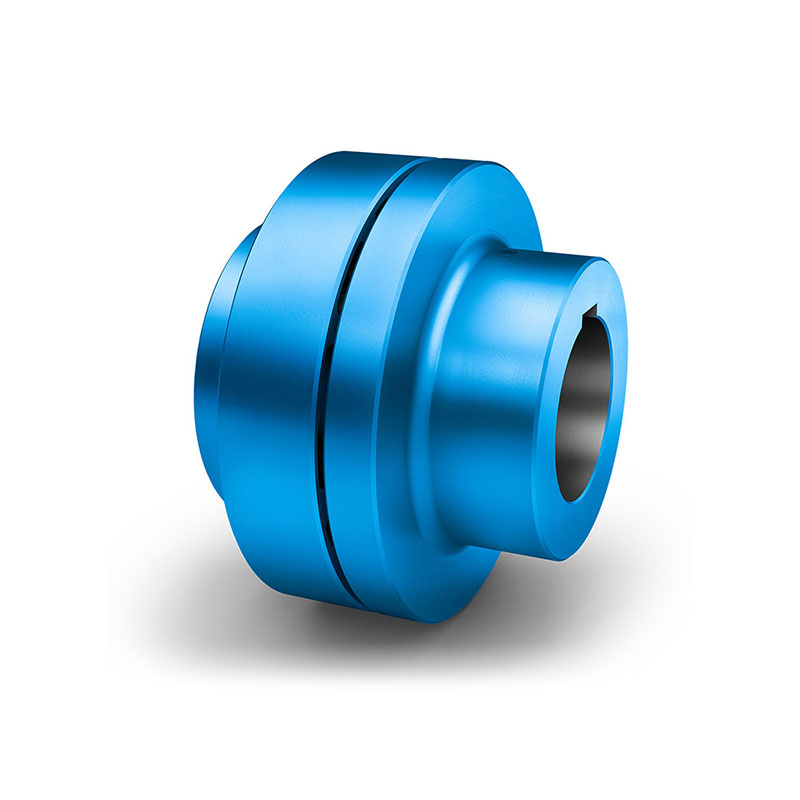

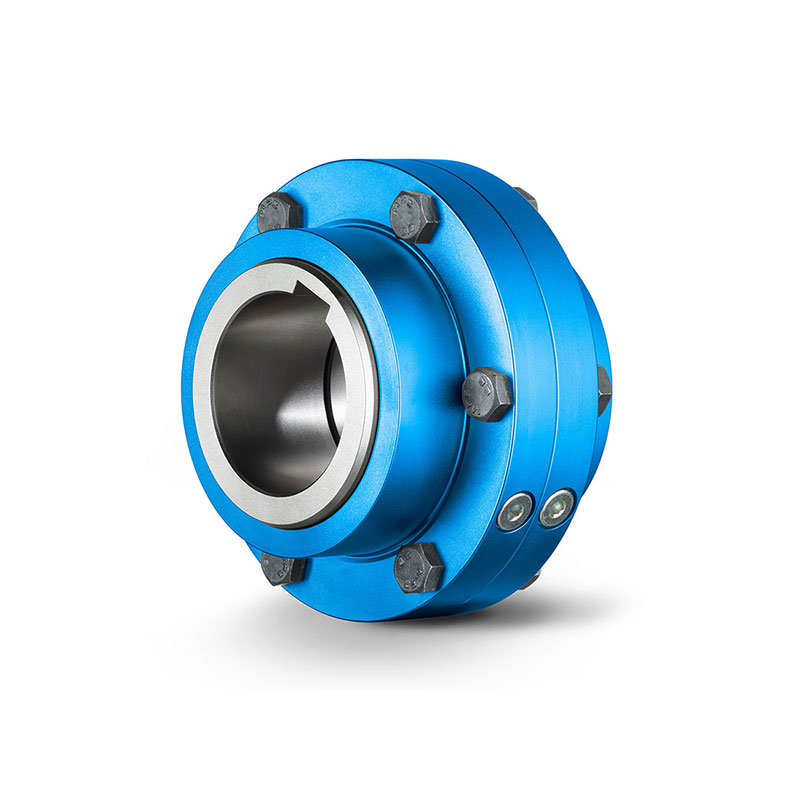

- Backlash-free, torsionally rigid all-steel multi-disk coupling

- Nominal torque range from TKN = 350 Nm to 28,000 Nm

- Temperature range: from –50 °C to +280 °C

The best-performing coupling on the market

Investment costs, lifecycle costs, power-to-weight ratio, fitness for use and the cost of purchasing couplings are key considerations for equipment manufacturers.

With the introduction of the new N-ARPEX® all-steel multi-disk coupling Flender is continuing the success story of the proven ARPEX® series of couplings.

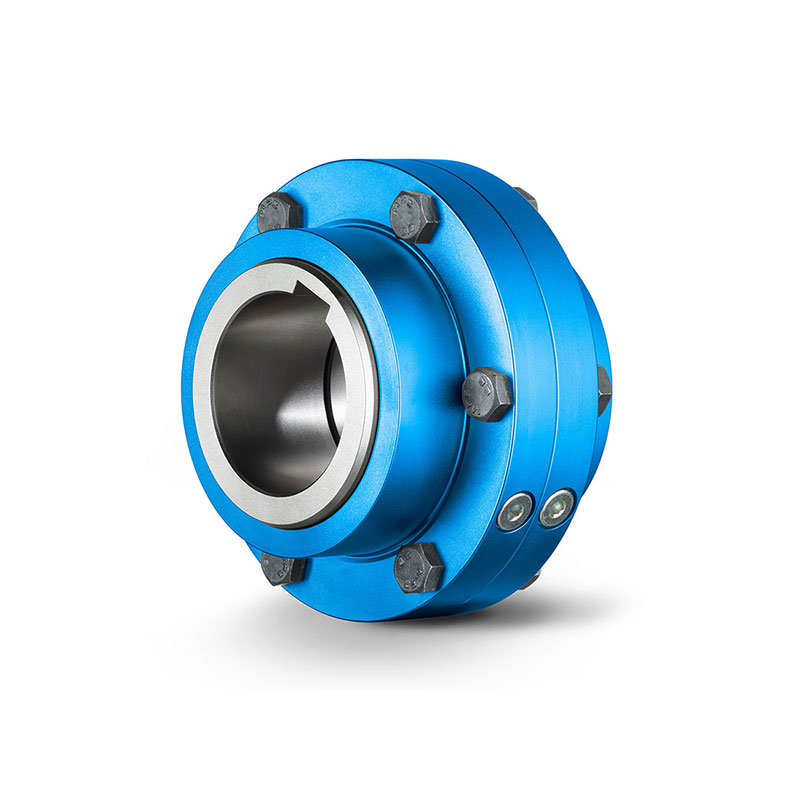

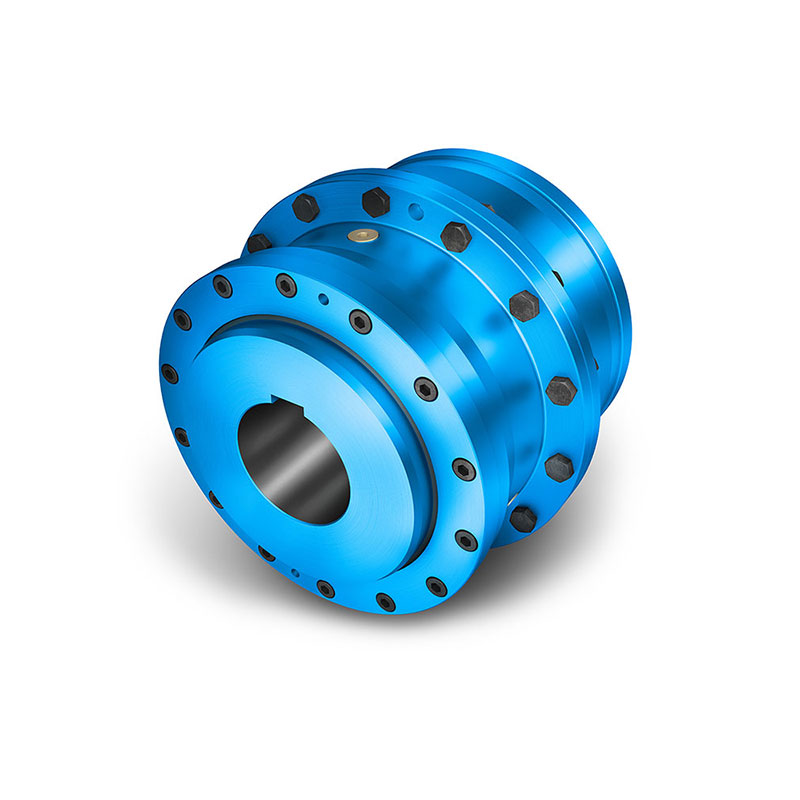

- Double-jointed gear coupling

- Nominal torque range from TKN = 1,020 Nm up to 162,500 Nm with 12 sizes

- Temperature range: from –20 °C to +80 °C

Strong and reliable: ZAPEX ZN® couplings connect machine shafts and compensate for angular and radial misalignment.

ZAPEX gear couplings from the ZN series are made of high-quality quenched and tempered steel and are manufactured according to the modular construction system.

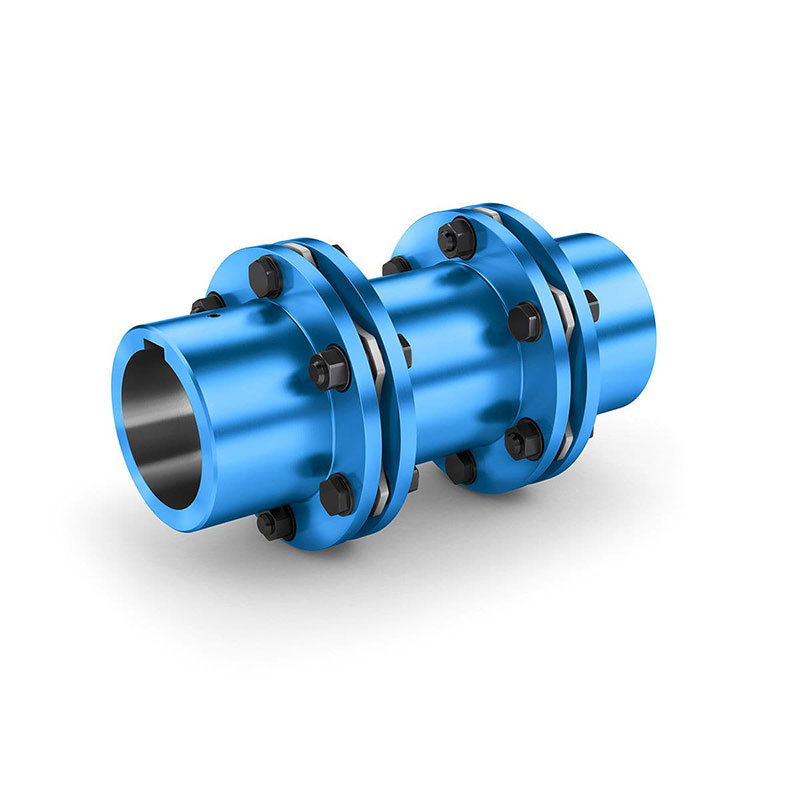

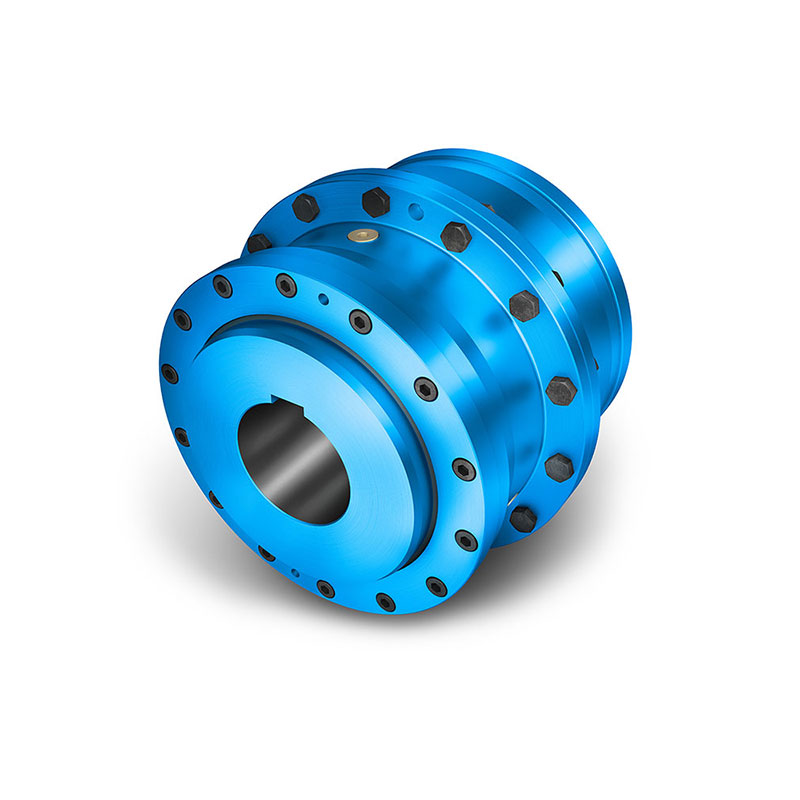

- Double-jointed gear coupling

- Nominal torque range from TKN = 1,300 Nm up to 7,200,000 Nm with 31 sizes

- Temperature range: from –20 °C to +80 °C

The double-jointed gear couplings of the ZAPEX ZW series compensate angular, parallel and axial misalignment of shafts. They are particularly suitable for use under rough operating conditions.

In addition to the standard series, couplings up to 13,500,000 Nm can be offered.

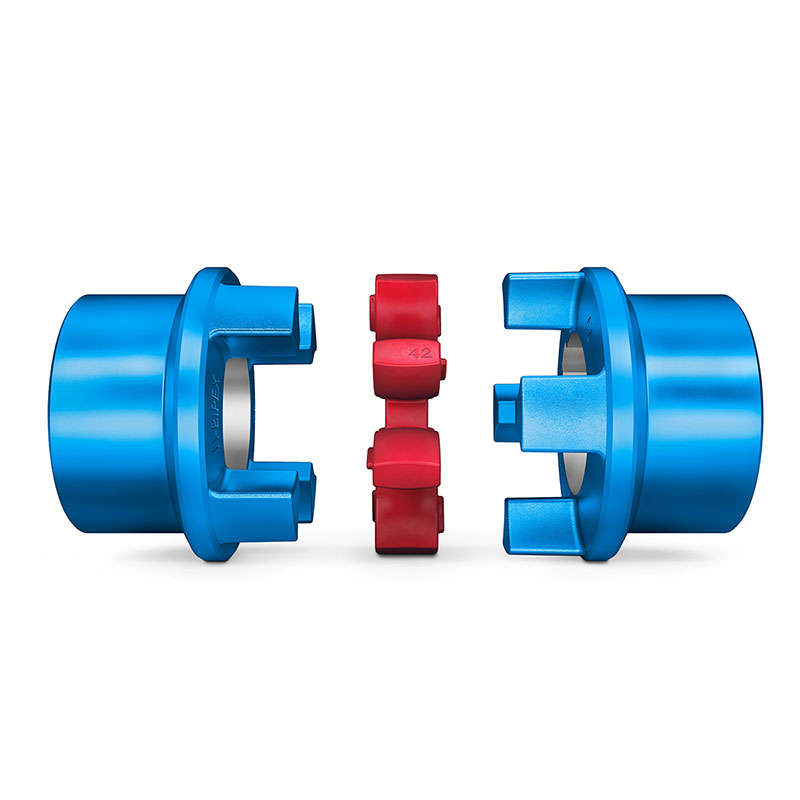

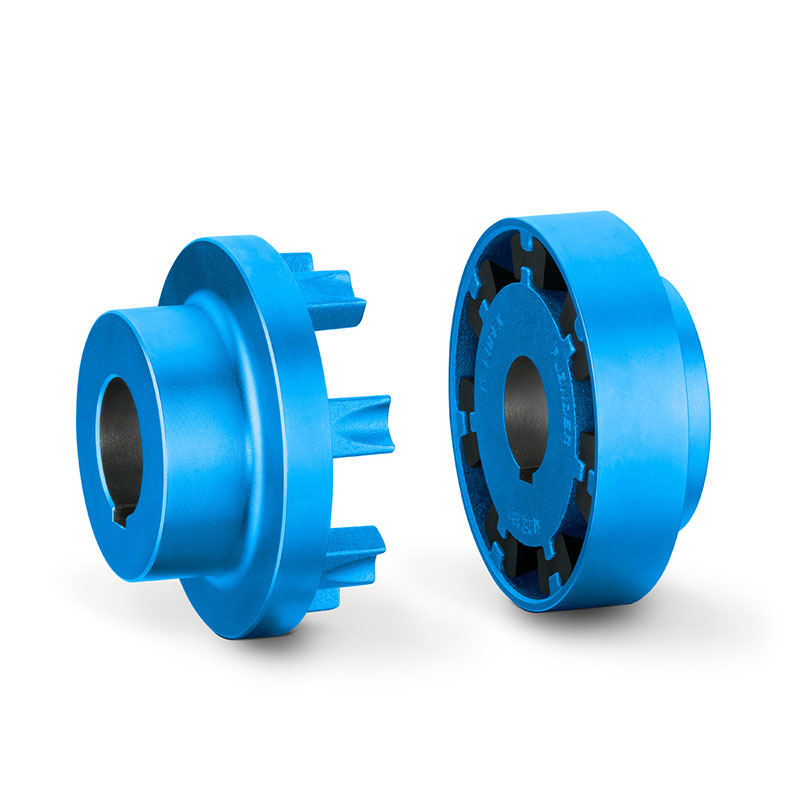

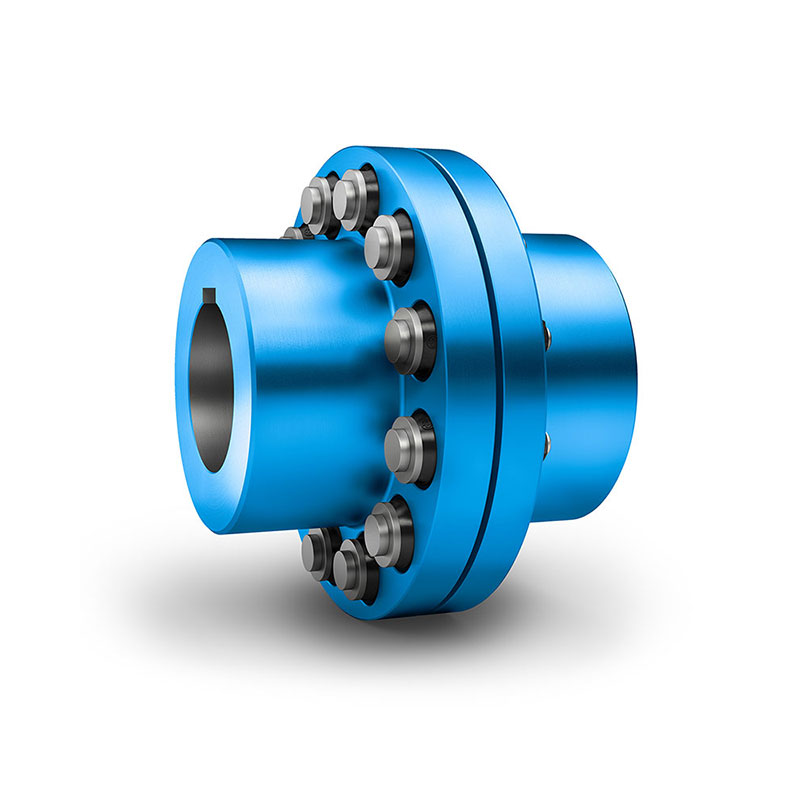

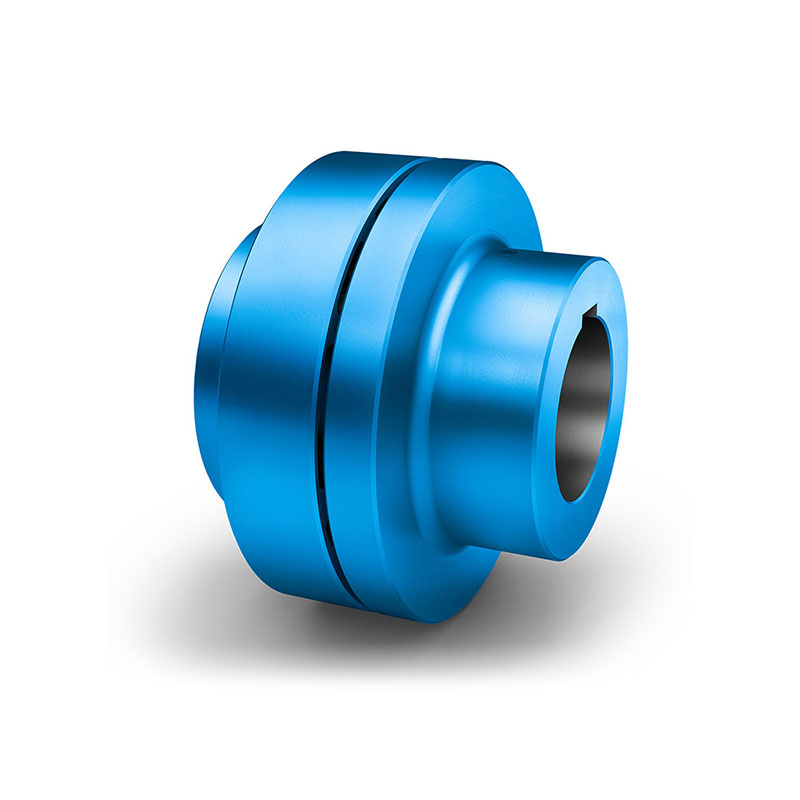

- Damping shaft coupling that can be used universally to compensate for shaft misalignments

- Nominal torque range from TKN = 60 Nm up to 21,200 Nm with 19 sizes

- Temperature range: from –50 °C to +100 °C

N-EUPEX DS couplings without fail-safe device allow positive disconnection of input and output side upon failure of the flexible elements due to overload or wear. Then, the metal parts of the DS coupling can freely rotate in opposite directions.

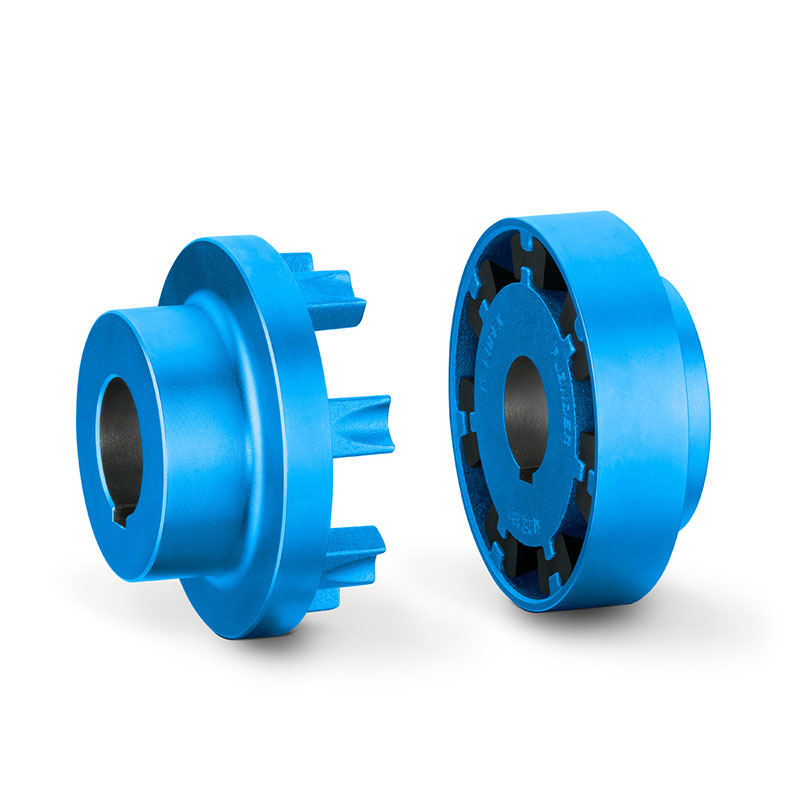

- Damping shaft coupling that can be used universally to compensate for shaft misalignment

- Nominal torque range from TKN = 19 Nm up to 62,000 Nm with 23 sizes

- Temperature range: from –50 °C to +100 °C

Due to their torsional flexibility N-EUPEX couplings offer the possibility of moving critical torsional vibrations from the operating area of the mechanical equipment in such a way that no negative effects on the drive train are to be expected. N-EUPEX couplings are made of high-quality cast iron. The flexible elements made of synthetic rubber (buna N) are available in different degrees of hardness for many applications. Metal pins and flexible elements are so designed that no wear occurs when properly fitted.